Hello,

A simple work around is to use the Delaunay 3D filter if adding thickness to a sphere. See the attached state file:

delaunay_3d.zip (393.0 KB)

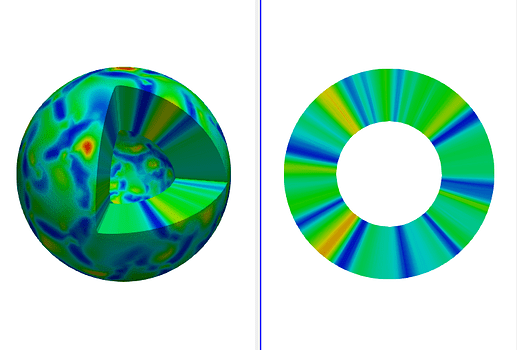

But, the cutting surface by the Clip filter with box might not be very sharp as shown in the upper left figure.